Using petroleum products is essential for daily life, but how can you keep the environment safe too? This is where petroleum testing comes into play. These tests are used to thoroughly test fuel, oil, biofuel and other petroleum products through which companies can identify harmful pollutants, ensure quality, and comply with regulations.

Petroleum testing checks the purity and quality of petroleum products at different stages of production from extraction through transportation, to refining and final use. It is also used in calculating concentration of metals like Iron, Copper, Chlorine, Sulfur etc. It involves studying and testing crude oil, its separated parts, fuel additives, any contaminants in the oil, and its environmental impacts. For the safety of the environment, it is important to find out the impurities and harmful substances present in fuel, lubricants, and other products.

Key factors highlighting the significance of petroleum testing include:-

Petroleum is a valuable resource that fuels the global economy, powering industries, transportation, and daily life. However, the extraction, transportation, and use of petroleum products come with significant environmental, health, and regulatory challenges. To ensure that petroleum is used and handled safely, testing plays a crucial role. Petroleum testing involves analyzing oil and its derivatives to assess their composition, quality, and potential impact on the environment. Below are the key factors that highlight the significance of petroleum testing in various industries and environmental sectors.

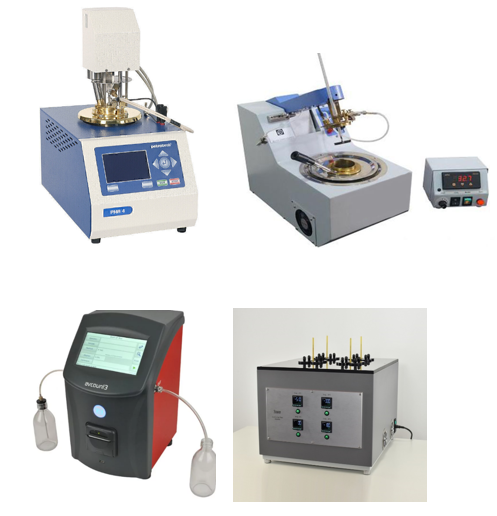

Reducing environmental impact:- The reason petroleum testing was introduced was to reduce the environmental impact of petroleum products on our planet. There are some harmful elements like Sulfur, heavy metals, Chlorine and Carbon compounds present in crude oil that can contaminate air, water, and soil when released. Companies need to invest in oil, Petroleum, lubricants and grease testing equipment to measure and reduce these elements to protect the environment as per ASTM and EU and other standards.

Meeting regulatory compliances:- Different countries have their own rules and regulations regarding the quality level of petroleum products. These rules focus on the safety of the environment and public health by reducing harmful pollutants and emissions. For example, if a regulatory agency sets a standard on fuel, this will help to control the Sulfur levels in petrol, diesel, biodiesel or lead quantity in gasoline. Regular petroleum lab tests will ensure the products comply with regulations preventing fines and legal issues for companies.

Ensure product quality and efficiency:- The aim of conducting the test is to maintain the quality and efficiency of the product. Poor quality fuel can result in engine wear, reduced fuel efficiency, and unnecessary expenses on repairing. With regular testing, it gets easier to monitor the performance. This helps fuel and lubricants work efficiently and perform longer, assisting manufacturers develop reliable products.

Detecting contaminants and preventing pollution:- There are chances of equipment damage, hazardous emissions, and pollution because petroleum products easily lose purity by water, debris, or any other chemical during production, storage, or transportation. Through contaminants tested in oil and grease, these problems can be prevented. Oil and grease testing equipment suppliers’ offer equipment that help companies detect contaminants early and take action before they reach the market.

Preventing equipment damage and operational delay:- Poor quality or contaminated petroleum products can harm industrial production equipment and machinery causing delays in operation and unwanted costly repairs. Regular petroleum testing helps in identifying the problem early on, preventing equipment from being damaged and keeping operations smooth. Testing the level of viscosity, flashpoints, color and contamination ensures that equipment functions properly, ultimately saving companies’ money and time. A reliable petroleum lab testing equipment supplier provides guidance on how you can protect your equipment and machinery from any type of damage.

Cleaner fuel: – With focus on cleaner energy, petroleum testing helps create fuels with reduced emissions. Testing and improving bio-fuels, synthetic fuels, lubricants, greases and other alternatives, help companies’ efforts to make fuels that are better for the environment. This reduces the pollution and supports global efforts to cut carbon emissions. Such changes are possible with the equipment provided by petroleum lab testing equipment suppliers.

Safety handling of petroleum products: – Safety in this field must be a top priority as petroleum products are highly flammable and also toxic at times. Testing reduces the risk of accidents. Testing flammability and flashpoints and safety-related factors are vital for safe handling throughout the journey from production to transportation. For the safety of employees and to protect the environment, oil and grease testing equipment suppliers offer instruments that measure these properties accurately.

Protection of water resources: – Accidental leaks or spills of petroleum products on water resources can have a huge impact not only on the environment but on human life. Detecting such properties through testing petroleum products early that have potential environmental risks help to prevent such issues. Knowing in advance prepares companies to adopt proper storage and handling practices to avoid spills and leakages. This safeguards water quality for human consumption and marine life.

Enhance sustainability by reducing waste: – When you know the defects, companies can recycle or reprocess them rather than discard them. This reduces wastage by ensuring that only high-quality, contaminant-free products are released for use. By associating with a petroleum lab testing equipment supplier, companies can access more eco-friendly testing solutions that contribute to sustainable practices.

Promoting industrial practices: – By prioritizing petroleum testing, companies show their dedication to environmental protection and responsibility toward industry practices. Regular testing ensures the company’s commitment to provide safe and high-quality products without affecting the environment. This is crucial to develop public trust in manufacturers and meet the expectations of increasingly eco-conscious consumers.

Protecting Wildlife and Ecosystems

Petroleum leaks and spills, particularly in marine environments, can have severe consequences for wildlife. The Deepwater Horizon oil spill in 2010 serves as one of the most notorious examples of how petroleum can wreak havoc on ecosystems, killing marine life, destroying habitats, and disrupting the food chain.

Petroleum testing plays a crucial role in detecting oil and petroleum-related pollutants in vulnerable ecosystems, including wetlands, forests, and aquatic environments. By regularly testing the quality of water, soil, and air, both environmental agencies and corporations can identify sources of pollution early, preventing widespread ecological damage. Early detection also enhances the effectiveness of cleanup efforts, minimizing long-term harm to biodiversity.

Access to advanced technology: – Petroleum product testing technology is improving significantly, making it easier for companies to carry out tests and obtain detailed information. Nowadays, petroleum product testing equipment is progressing to the level where one can get precise data on various properties, allowing companies to have accurate control of quality. Collaborating with an experienced petroleum lab testing equipment, a supplier gives companies access to advanced technology with full automation and tools to improve testing accuracy.

Economic benefits: – Testing helps every company not only to protect the environment but also add economic benefits. By following regulatory compliances and maintaining product quality, companies can avoid fines, reduce waste, and prevent costly equipment damage. Companies have the benefit of maintaining its profitability while safeguarding its reputation and brand among customers.

Hence, petroleum product testing proves to be essential for environmental protection, compliance with regulations, and overall product quality. Regular testing enables companies to prevent contaminants, and reduce pollutants promoting sustainable practices. Choosing a trusted supplier for high-quality petroleum lab testing equipment is a key step in achieving these goals which help companies support safe operations.

Conclusion: –

Petroleum testing is not just a technical requirement; it is a vital tool for ensuring environmental protection, regulatory compliance, and the sustainability of natural resources. By detecting pollutants, ensuring safe handling and disposal, and supporting effective spill response, petroleum testing helps reduce the ecological footprint of the petroleum industry. As environmental challenges continue to grow, the role of petroleum testing will only become more critical in safeguarding ecosystems, human health, and the planet’s future.

In an era of increasing environmental awareness, the importance of petroleum testing cannot be overstated. For businesses, compliance with environmental standards is no longer a matter of choice—it’s a responsibility. Investing in regular petroleum testing ensures that industries are doing their part to protect the environment while maintaining operational integrity and reducing their ecological impact.