In industries where quality and safety are not compromised, Fourier Transform Infrared Spectroscopy with Attenuated Total Reflectance (FTIR-ATR) has emerged as a cornerstone technology. By delivering rapid, non-destructive analysis, FTIR-ATR is a powerful technique transforming how pharmaceuticals and food manufacturers verify raw materials, ensuring compliance, authenticity, and consumer trust.

What is FTIR-ATR?

FTIR-ATR combines infrared spectroscopy with a sampling technique that requires minimal preparation. A crystal (like diamond or zinc selenide) presses against the sample, measuring its infrared absorption. This generates a unique “chemical fingerprint” in seconds, ideal for identifying compounds without altering the sample.

Pharmaceutical Applications: Precision Meets Compliance

- Raw Material Verification: Pharma companies use FTIR-ATR to confirm the identity and purity of excipients, active pharmaceutical ingredients (APIs), and other components. A quick scan detects discrepancies, preventing costly formulation errors.

- Counterfeit Detection: With counterfeit drugs posing global risks, FTIR-ATR compares suspect samples against authentic references, exposing fake or substandard products.

- Batch Consistency: Ensuring uniformity in drug formulations is critical. FTIR-ATR monitors batch-to-batch variations, maintaining efficacy and regulatory compliance (e.g., FDA, EMA guidelines).

- Additionally, FTIR ATR helps control quality during the manufacturing process. It enables fast and reliable monitoring of the material’s properties, ensuring consistency in batch-to-batch production and helping to meet regulatory standards.

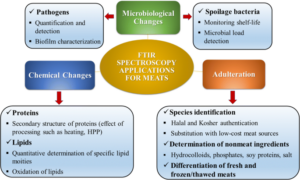

Food Industry: Safeguarding Quality and Authenticity

- Adulterant Detection

FTIR-ATR identifies contaminants like melamine in milk or palm oil in olive oil, protecting against economically motivated adulteration. - Ingredient Authentication

Is that “pure” vanilla extract genuine? FTIR-ATR verifies the chemical profile of spices, flavors, and additives, ensuring label claims match reality. - Quality Control

From checking moisture content in grains to analyzing fats in dairy, FTIR-ATR ensures raw materials meet safety and nutritional standards.

Furthermore, FTIR ATR is used for rapid detection of contaminants or impurities in food raw materials, such as pesticides or chemical residues, ensuring that the food products are safe for consumption and free of contaminants.

Why FTIR-ATR Stands Out

- Speed: Results in seconds, ideal for high-throughput environments.

- Non-Destructive: Preserves samples for further testing.

- Versatility: Analyzes solids, liquids, gels, and powders without complex prep.

- Cost-Effective: Reduces reliance on solvents and lengthy procedures.

The Future of FTIR-ATR

As Pharma and Food industries face tighter regulations and rising consumer demands, FTIR-ATR’s role will expand. Advances in portable devices and AI-driven data analysis promise even faster, on-site decision-making—from factory floors to supply chains.

Conclusion: Trust, Verified

FTIR-ATR bridges the gap between innovation and integrity, empowering industries to deliver safe, authentic products. In a world where every molecule matters, this technology isn’t just a tool—it’s a guardian of quality.

Its ability to analyze materials without the need for extensive sample preparation or destruction makes it an indispensable part of quality assurance. As industries continue to demand higher standards of safety and quality, FTIR ATR will remain a key technology for ensuring the integrity of raw materials in these critical sectors.